PTFE Coated Glass Fabrics

We offer all standard PTFE coated fabric types.

However, should your application require materials which offer higher performances, we are your correct point of contact.

The various qualities of coating for glass and aramid fabrics are defined mainly by the percentage of PTFE used. The final nominal thickness plays a lesser roll. We can define the percentage of PTFE for your specific application. A highly sealed surface can be made by using specified top coats or laminating fluoroplastic films. This can substantially increase the life time of PTFE coated fabrics for various applications, improving cost effectiveness.

Technical Characteristics:

- Temperature resistance from – 150 °C to + 260 °C continuous, short term + 300 °C

- Tear resistant and dimensionally stable

- Excellent release properties

- UV-IR and Hot air resistant

- Resistant to almost all known chemical products and solvents

- Physiologically harmless – food approved

Availability and Options:

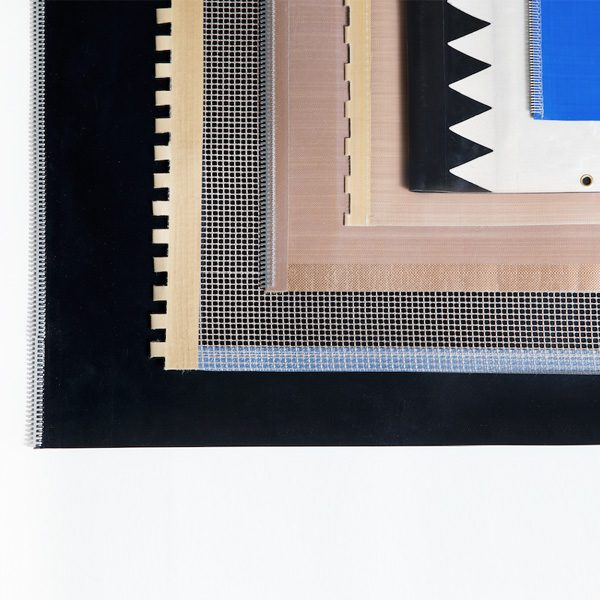

- Nominal Thickness: from 0.07 mm to approx. 1.00 mm

- Widths: from 3 to 4,800 mm. Standard widths 1 m and 2 m

- Roll-good: standard roll length 30 m

- Cut pieces according to your technical drawings

- Closed or open mesh

- Porous

- Anti-static or none anti-static

- Self-adhesive or none self-adhesive

- Heat sealer tape with paper or filament strips, zone tape or with the adhesive material washed out in the middle

- Laminated on one or both sides

- With additives, for example peek or aluminium

- As an assembled transport belt, endless woven also available

We look forward to your inquiry

synthetica® your partner for PTFE Coated Glass Fabrics